BioBots

3D printing is a technique used to translate 3D models, developed using CAD software, into physical objects. It offers the prospect of rapid prototyping, replacing labor and time-intensive machine shop-based prototyping. Furthermore, 3D printing is already being used in manufacturing processes and has found applications in the aerospace, construction, and architecture industries. While 3D printing is now also being used for device development in the biomedical field, there are currently no 3D printers on the market which are capable of producing products in a sterile environment at a cost effective price, that’s where BioBots comes in.

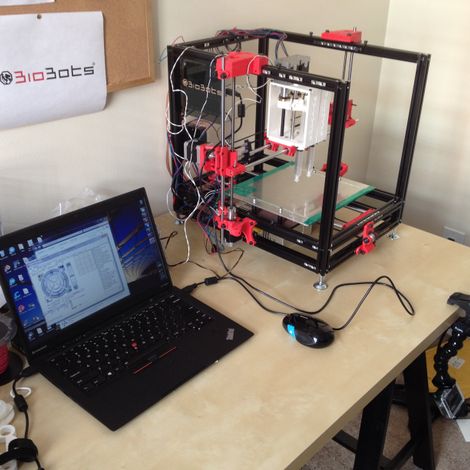

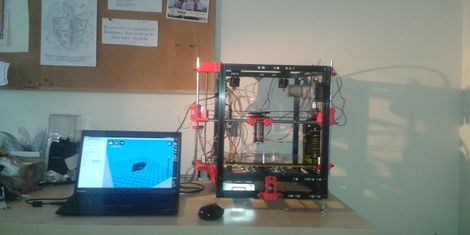

The framework of our printer consists of a stainless steel frame and polyactide plastic parts. The plastic parts hold the smooth rods along which bearings slide to allow the extruder to move in two dimensions and the base in one dimension to allow 3D control. The motors, pulleys and belts have been mounted. A motherboard is also mounted on the printer that allows control over the extruder, motor, and hotbed. The material that is being printed is ejected onto the printing surface using a unique extruder to which syringes of different volumes and gauges can be attached. Additionally, the printer will have the flexibility in the future to use 4 extruders, giving researches the ability to print with different materials and different cell types.

The printing surface and the extruder will be enclosed using clear plexiglass sheets and the atmosphere inside will be purified using a High-Efficiency Particulate Air filter similar to those currently used in medical facilities and biological safety cabinets in research labs. We will create a flow environment by placing a large cost-effective fan on top over the filter. Maintaining a sterile printing environment will allow users to transfer tissues directly to in vivo experiments at a cost-effective price; a significant step towards the production of artificial tissues.

vimeo.com/89889925